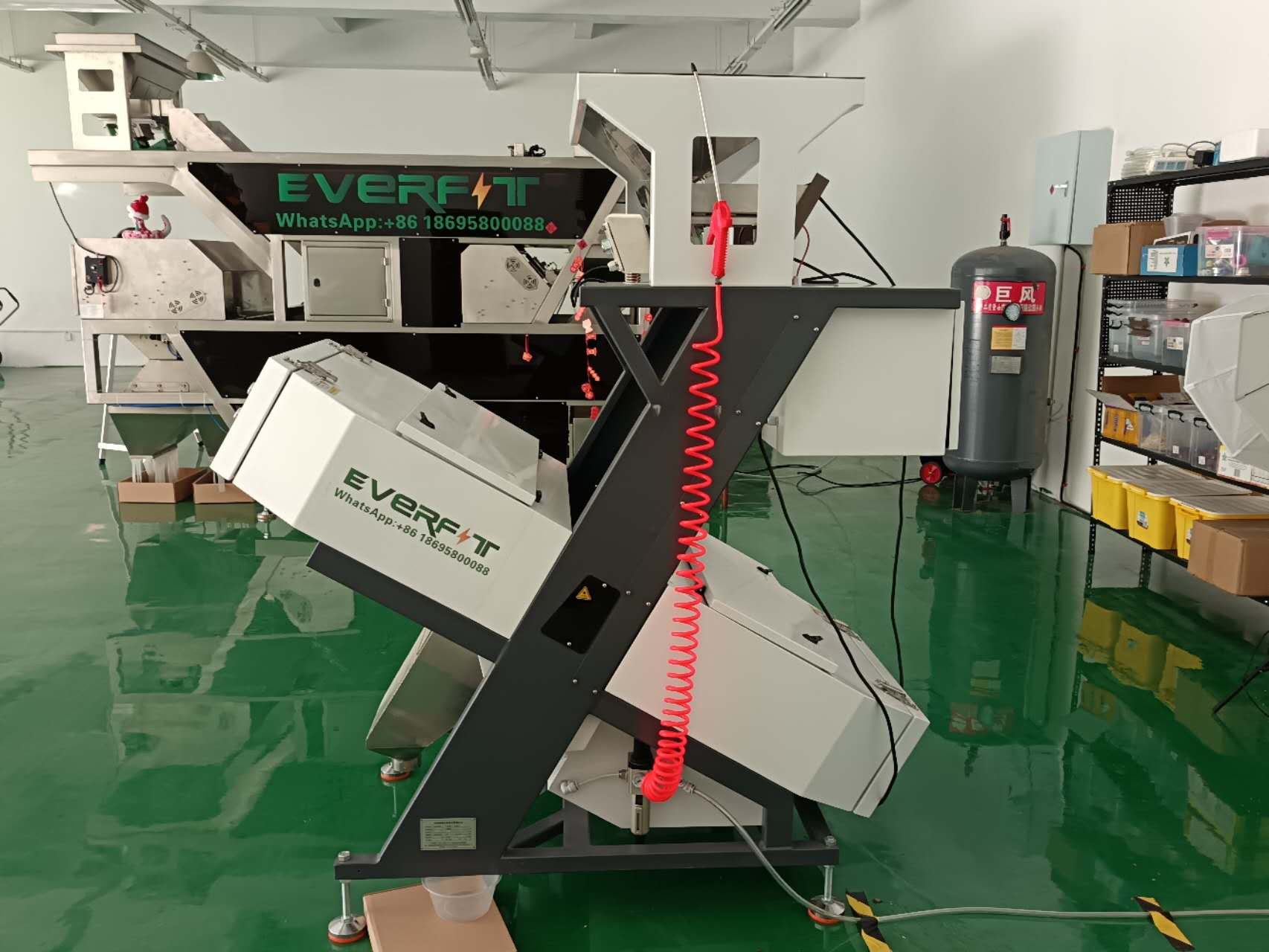

Application of color sorter in the nut industry in the Middle East

In the Middle East, with its unique climate and geographical conditions, the nut industry is extremely prosperous, with a large number of crops such as pistachios, almonds, cashews, etc., making it an important global nut producing area and consumer market. In this market full of opportunities, color sorting machines have quietly become the core force for the transformation of the nut industry.

In the sorting process of pistachios, the role of the color sorter is crucial. The quality of pistachios is greatly influenced by color, degree of opening, and plumpness of the nuts. The color sorting machine utilizes an optical detection system to keenly capture abnormal fruits such as yellowing and blackening. At the same time, it can accurately identify and remove pistachios with abnormal openings, incomplete or broken kernels, ensuring that the pistachios introduced to the market have superior quality and attractive appearance.

For almonds, the color sorter also excels. Almonds have strict requirements for appearance, color, and integrity. With advanced technology, the color sorter can effectively detect surface black spots, mold, and fine cracks. It can also screen based on color differences and finely grade according to size, shape, and other characteristics to meet different customer needs and significantly enhance product added value.

Cashew nuts are prone to impurities such as broken shells and stones during processing, and may also suffer from insect infestation and mold growth. The color sorter uses high-resolution image acquisition and intelligent algorithms to quickly and accurately screen out impurities and defective cashews, ensuring the purity and beauty of cashew products.

The application of color sorting machines has greatly improved the product quality of the nut industry in the Middle East, effectively removing impurities and defective products, ensuring food safety, and enhancing market competitiveness. Its automated continuous operation mode can process several tons of nuts per hour, greatly improving production efficiency and reducing labor costs. However, there are currently challenges such as high equipment costs, difficulties in adapting technology, and insufficient personnel training. But with the development of the industry, color sorting machines will continue to innovate towards intelligence, multifunctional integration, and energy conservation and environmental protection, injecting strong impetus into the vigorous development of the nut industry in the Middle East.

Mobile/Whatsapp 0086-18695800088

Mobile/Whatsapp 0086-18695800088